Anglesey Aluminium Remediation

Treatment of Three Distinct Hydrocarbon Plumes

Brownfield Awards: Winner of Best Remediation of a Smaller Site

Decades of heavy industrial activity on the former Anglesey Aluminium site had left a legacy of significant contamination, with diesel leaks from underground tanks, oil spills from industrial compressors and fire damage incidents leading to transformer oil spills. Detailed characterisation and pilot testing enabled the design of a in-situ treatment solution aimed at addres ing not one contaminant plume, but three separate impacts covering an area of <0.5 hectares.

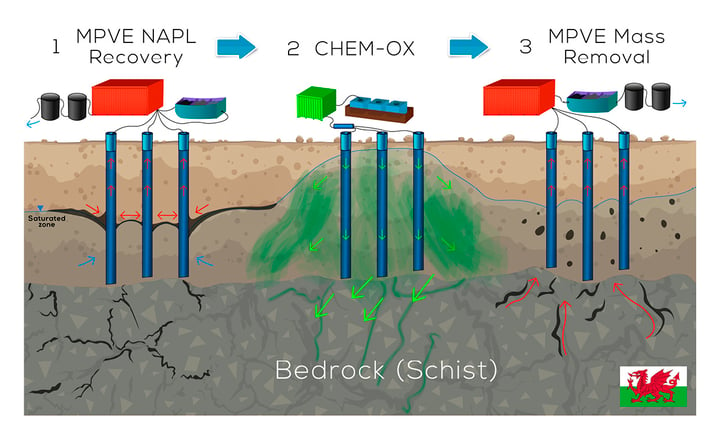

The approach incorporated Multi-Phase Vacuum Extraction (MPVE) to remove Light Non-Aqueous Phase Liquid (LNAPL) from the groundwater; pumping and chemical injection to treat residual dissolved phase contamination. Treatment targeted saturated soils and groundwater within the complex geological setting of made ground, superficial gravels and an underlying fractured schist bedrock.

This combination of techniques successfully removed all detectable LNAPL and achieved a reduction in dissolved hydrocarbon concentrations, in all areas, of greater than 95%, As a result,regulatory approval of the works was secured and the development potential of the site was unlocked. This approach provided a cost-effective solution, incorporating not just best practice measures, but enabling the best feasible remediation process to be implemented.

Characterisation

The former Anglesey Aluminium site looms large over the island and its iconic stack can be seen from the hills of Snowdonia. Regeneration of which promises to change the site from the UKs largest electricity consumer (until its closure in 2009), into a sustainability focussed Eco-Park, including a biomass power station, bringing employment and investment to the area.

Detailed investigation identified three areas of concern. A plume was encountered around a former Compressor House where up to 750mm of lubricating oil was pooled on the groundwater and a 2,500m2 plume of diesel, associated with a former Above Ground Storage Tank (AST). Vertical delineation exposed contaminant spread within fractures into the underlying schist.

A second impact resulted from a fire in a transformer within an electric substation, known as the Rectifier Yard, converting AC to DC for the smelting process. Migration over years had spread the LNAPL up to 700mm in maximum thickness, with an associated dissolved plume extending across an area of approximately 1,500m2.

A third, smaller impact, approximately 200m2, was associated with a diesel spill at a vehicle fuelling station. Following removal of the underground storage tanks (USTs) a dissolved phase plume remained in the superficial gravels across the former forecourt and had migrated vertically into the bedrock close to the tank farm.

Geo2s first steps were to undertake treatability trials in key areas, the recoverability of the NAPL and groundwater was tested together with lab scale trials of chemical performance within the substrate. Six oxidant mixtures were trialled to optimise the chemical injection design to treat all three contaminant types on the site.

In all areas the bulk of the contaminant plume was associated with key high permeability flow zones typically between 3-5m bgl within the superficial deposits, but also intersecting with fracture networks within the bedrock, in some areas, up to 10m bgl.

Deployment of Geo2s Environmental Permit ensured protection of the environment, beyond the mitigation of the known groundwater impacts. Compliance and competence was central to the implementation of this strategy, preventing spills or leaks, minimising emissions and governing discharges to coastal waters, working with NRW throughout the whole process.

Implementation

Following the high definition pilot works, treatment in the Compressor House and Rectifier Yard comprised LNAPL removal using a Multiphase Vacuum Extraction (MPVE) plant. This technology applies a high vacuum across the surface of the groundwater across the plume, using, large diameter, high-porosity remediation wells to recover the LNAPL by establishing a negative pressure gradient within the targeted flow zones.

This robust design, focused on best feasible treatment, balancing the needs of the client whilst embracing the SuRF UK approach to sustainable remediation; minimising offsite disposal, avoiding demolition (of buildings with a value to the final development) and ensuring treatment within the schist bedrock, provided sufficient confidence to be fully supported by the regulator, National Resources Wales (NRW).

Implementation of this combination of techniques allowed a phased treatment utilising modular plant. This enabled rapid redeployment of the plant following successive treatment of each remote impact on this vast site, minimising the cost of the works, whilst prioritising treatment in areas to suit the development programme.

Treatment

This approach successfully recovered all measurable NAPL within 6 weeks, with a further 6 weeks of pumped groundwater recovery minimising the risk of rebound and achieving a mass recovery of dissolved phase contamination.

Following NAPL removal, an intensive chemical injection programme, comprising two successive applications of Fentons based chemical oxidation, activated by naturally elevated FeII within groundwater, was undertaken in all three areas. The oxidant was mixed into a solution at the desired concentration by in-line dosing equipment and injected under pressure using high pressure pumps (up to 180psi) driving the liquid through the superficial matrix and into the fracture zone, maximising direct contact oxidation. By focussing the bulk of the treatment-agent into the most impacted areas, the injection effectively targeted the residual source. Contamination in the schists demonstrated the presence of vulnerable fracture zones, high-pressure injection of oxidant exploited the same flow pathways treating the dissolved phase impact within the bedrock.

Oxidant injection was repeated in each area within two weeks of the first application promoting a sustained reaction and allowed for oxidation of contaminants desorbed and mobilised by the first injection, to achieve optimal contaminant destruction.

A total of 720m3 of oxidant was applied in the Compressor House, with a further 600m3 in the Rectifier Yard and 80m3 in the Garage areas.

Results

Application of the high vacuum recovery system achieved removal of all measurable LNAPL in each area. The subsequent chemical injection totalled an application of 1,400m of oxidant over a six-week period across the three areas. Oxidant application was tailored in each location to the differing contaminant type, concentration and distribution, and achieved reductions in TPH concentration in excess of 95% in diesel, transformer oil and compressor oil impacts, within the superficial deposits.

- Reductions in each area were achieved from peaks concentrations of 710,000μg/l in the diesel and lubricating oil impacted Compressor House to a worst case 806μg/l;

- 4,400,000μg/l in the transformer oil impacted Rectifier Yard to worst case 2,012μg/l; and,

- 120,000μg/l to 1,787μg/l in the diesel impacted Garage area.

Maximum concentrations in the deeper aquifer were comparatively low (peaking at 4,600μg/l), with improvements in the schists in excess of 75% in both the Compressor House and Garage areas.

Comparing the results of the treatment against the 80-90% improvements anticipated in the chemical oxidant pilot trials, demonstrates that the treatment has been highly successful. The addition of the post chemical oxidation groundwater mass recovery serving to ensure a higher degree of treatment than would have anticipated by the LNAPL removal and oxidant application alone.

Outcome

Validation sampling exhibited sustained improvements and steady state conditions in each area of the site. The strength of the data and quality of the groundwater monitoring was sufficient to demonstrate to the regulator, NRW, that the objectives of the remedial works had been achieved.