Dual Phase Vacuum Extraction and Chemical Oxidation

The investigation of the site’s groundwater and soils showed significant concentrations of Free Phase Product (FPP) and dissolved petroleum hydrocarbons, centred on an ageing collection of underground storage tanks to the rear of the forecourt. A plume of contamination was identified flowing across the site.

The contamination posed a potential risk to the neighbouring watercourse via groundwater migration whilst vapours emanating from the site threatened to affect nearby residents.

An approximate treatment area of 750m3, situated between two metres below ground level (mbgl) and 5mbgl. A number of further wells were drilled to monitor potential migration.

The resultant remediation project was divided into three stages

Stage 1

Before removing all the underground fuel storage tanks and associated piping, we first applied a bentonite seal around a deep drain which intersected the contaminant plume. This was designed to prevent migration of FPP through the more permeable materials surrounding the drain.

Stage 2

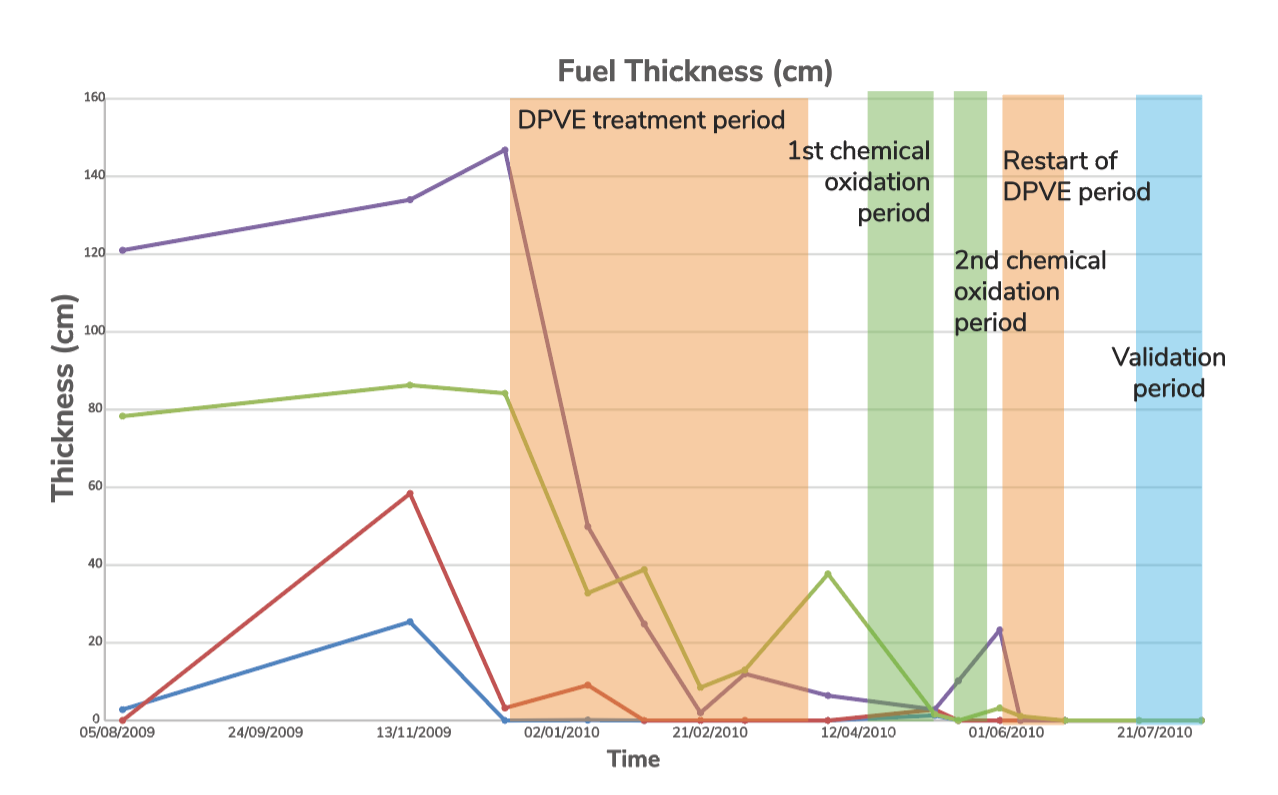

This enabled us to begin product skimming and operate a Dual Phase Vacuum Extraction (DPVE) system to remove fuel and treat contaminated groundwater.

Stage 3

The final stage of the remediation coupled the DPVE system with a programme of in-situ chemical oxidation, to reduce residual hydrocarbon concentrations.

Innovation

During the planning of the remediation project, Geo2 uncovered an innovative, waste-free solution for the treatment of waterborne organic pollutants such as the hydrocarbons in the waste stream.

Developed by Arvia Technology Ltd, the novel water treatment method is based around a patented adsorption material, Nyex®, which is regenerated during the treatment process, making it a more sustainable option than traditional Granular Activated Carbon (GAC). This process uses electrochemical oxidation to break down organic contaminants into

CO2 + H2O. Successfully achieving sustainable disolved phase treatment of waste water.

Arvia successfully treated contaminated water at the site alongside Geo2, earning the collaborators a prestigious Brownfield Briefing Award for ‘Most Innovative Remediation Method’.

Results

A reduction in hydrocarbon contamination of between 99% and 100% in the worst affected areas of groundwater were achieved.