Surfactant Enhanced Oil Recovery

A former industrial site in North London was contaminated with a 100m long plume of oils, stemming from historical fuel oil storage onsite. Rapid action was required to address perceived risk to a local watercourse. Groundwater pressure was confining the oil beneath a layer of clay, this prevented effective recovery by conventional techniques. Geo2 undertook a bench scale testing programme using samples from site to design a suitable means of oil recovery.

Treatment Design

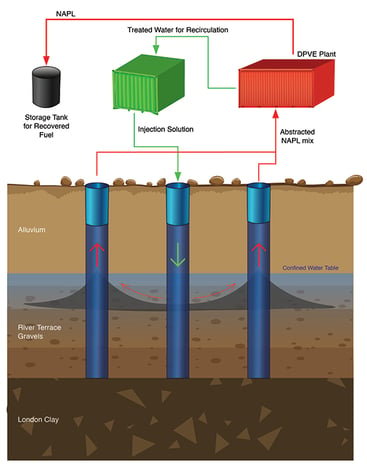

Bench scale testing demonstrated flushing of the subsurface with a bespoke surfactant to mobilise the oils from the ground and a series of recirculation cells established, with surfactants injected around the perimeter and recovered in a central abstraction well, flushing the chemicals through the ground and recovering mobilised oils.

Results

This technique achieved recovery of over 80-85% of the mobile oils within the subsurface over a two month treatment period; subsequent validation sampling demonstrated to regulators that the risks had been mitigated, with the efficient project closure recognised with an industry leading Brownfield Briefing Award.

Detailed Evaluation

Background

Preliminary Investigation works identified a plume of heavy oils approximately 100m long, floating on the groundwater beneath a former industrial site in North London. Stemming from historical oil storage, this impact had spread laterally in the direction of groundwater flow. Geo2 were commissioned as this plume of contamination presented a serious risk to the local watercourse.

Remediation Design

A rapid solution was required to alleviate the potential for environmental harm, and to remove planning obstacles for development. Sub artesian pressure within the underlying gravels confined the viscous oils on the underside of low permeability clays, present across the site, which restricted the ease of recovery by conventional techniques.

Bench Testing

Using bench scale trials to establish the precise chemical makeup and conditions in the subsurface Geo2 were able to design a bespoke solution, involving injection of a surfactant compound, a polyester glycol, to lower the surface tension of the oils with a high alkalinity solution, enhancing mobility of oils in the environment.

Trials indicated that subsurface engineering, using these methods would enable a pumped recovery of oils.

Main Phase

- A network of over 100 wells, drilled using rotary and sonic methods, were installed as dual purpose abstraction and injection points.

- A total of 21 overlapping recirculation cells were formed.

- At the centre of each cell surfactant rich groundwater was injected under pressure, whilst the peripheral wells recovered the surfactant, groundwater and mobilised oils.

How it works

Each recirculation cells established a steep hydraulic gradient around the abstraction borehole, encouraging rapid flushing of the surfactant through the formation from the boundary injection points to the centre of each cell. pH adjustment mobilises the oils trapped beneath the overlying clays by the sub-artesian effects.

The surfactant forms micelles around the desorbed contaminant, trapping it in suspension.

Mobilised product was removed using vacuum extraction and oil water separation techniques, which also enabled the recovery of surfactant compounds for reuse onsite.

The recycling and reinjection of surfactants along with treated groundwater minimised injection costs and ensured the entire plume was treated with only 3,000 litres of surfactant, which could be recovered from the environment upon completion of the works; delivering a highly sustainable remediation strategy.

Results

This flushing process was conducted until 1.5 pore volumes of each cell had been injected and the surfactant compounds flushed through.

This achieved maximum recovery of oils, based on bench scale trials. Oils were flushed from the entire plume area over a two month period, during which 1,448m3 of groundwater was recirculated. Subsequent borehole testing indicated over 80-85% of all mobile oils has been recovered from the formation.

Conclusion

Validation monitoring across the plume area echoed the results of the bench scale trials, demonstrating the success of the treatment programme, allowing the regulators and Client to have confidence in the outcome of the remediation.

Award Winning

These advanced characterisation techniques, using both laboratory and site testing and modelling enabled a detailed and rigorous schedule of monitoring to be undertaken, these included pre and post treatment bail down testing, colorimetric LNAPL determination in surfactant systems and pH monitoring of subsurface distribution, proved remedial efficacy. This was judged to be the Brownfield Briefing, Best Project Closure and Verification Award Winners., 2015