Soil Stabilisation and Chemical Oxidation Treatment of Tars, Hydrocarbons and Chlorinated Solvents

Overview

Historical Contamination Liability

Historical infilling of a river channel with refinery wastes, including tars, presented a significant barrier to the regeneration of a former industrial facility and gasworks site.

The tars present within made ground deposits and contamination associated with other industrial processes formed two plumes within the groundwater, which regulators were concerned presented a serious threat to nearby controlled waters.

Integrated Treatment Design

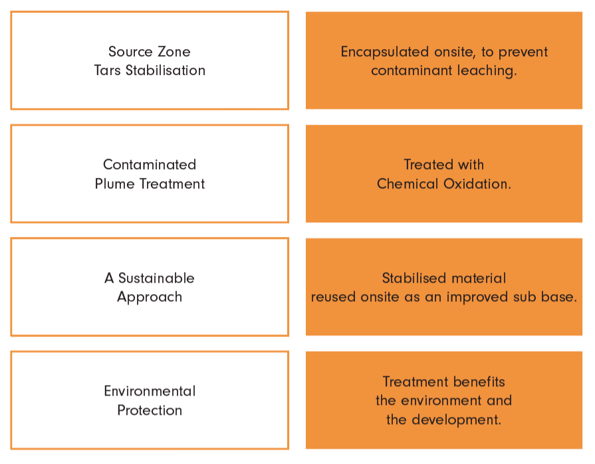

A remediation strategy was designed to achieve:

Pilot Testing

To provide the Client, Consultant and Regulator confidence in the solution, pilot testing was undertaken to determine the ideal stabilisation mix and most suitable oxidant.

Contamination Treated

- Circa 18,000m3 of tar contaminated soils were stabilised to form a development sub base for regeneration of the site.

- Dissolved contaminants, forming two plumes in the underlying gravel aquifer were treated with circa 3,000m3 of activated chemical oxidants across a four week period.

- Contaminated water from construction and remediation excavations was treated onsite.

Sustainable Remediation

- No soils left site as part of the remediation works.

- Water used in the chemical oxidation was sourced onsite from a deep abstraction borehole.

Phased treatment ensures that development could commence in key areas within 3 months.

Detailed Evaluation

Regeneration

The Clients objective to redevelop a former industrial facility became focussed upon the need to resolve potential environmental liabilities and to improve the geotechnical stability of poorly consolidated historic fill material.

Impact

Several phases of investigation were undertaken by the supervising consultant and a range of contaminants encountered:

- Acid tars were present throughout 3m of tipped fill material across an area of 12,000m2.

- Two main plumes containing a mix of dissolved long chain hydrocarbons in excess of 30mg/l and chlorinated solvents present with a shallow gravel aquifer, in connectivity with a nearby water course

Bespoke Solution

A programme of pilot testing was undertaken entailing recovery of soil cores, groundwater and bulk samples of aquifer matrix in order to optimise design by testing:

- The performance of various oxidants in the subsurface through bench scale testing.

- Leachability tank and strength testing on stabilised trial monoliths of site materials.

This approach offered certainty to all stakeholders in the efficacy of the treatment solution, before any site works were commenced.

To maximise sustainability and minimise waste, all soils were stabilised for reuse onsite and all groundwater remediation was undertaken insitu.

Soil Stabilisation

A phased approach was undertaken to ensure the Clients development programme could be expedited.

Stabilisation works were spilt to ensure the proposed main building area was treated and validated to demonstrate both geotechnical strength and minimal leachability, to permit development.

Detailed Evaluation

Stabilisation Validation

Strength testing proved the stabilised material had a safe bearing capacity of over 450kN/m2, over 3 times the required threshold.

Leachability testing of stabilised materials demonstrated no potential future risk to controlled waters.

Chemical Oxidation

Chemical injection works were undertake following completion of stabilisation works in each area:

- This comprised the installation of 67 wells into the underlying gravel aquifer, across two plumes, all installed to permit targeted, high pressure injection of oxidants.

- Approximately 3,000m3 of Modified Fentons Oxidant was injected across the treatment areas over a 4 week period.

- Mixed onsite using peristaltic dosing equipment, a supply of safely mixed oxidant was available for injection at rates of upto 180,000 litres a day.

- A 90m3 storage tank was constructed to facilitate this large water requirement, fed by a 60m deep borehole into the underlying aquifer, installed specially for this task.

Risk Mitigated

The successful encapsulation of the source tars into a stabilised monolith provided a sub base ideal for the development, whilst also removing the potential environmental liabilities arising from an historical contaminant source.

Significant reductions were observed in contaminant concentrations in both groundwater plumes, neither of which demonstrated rebound ensuring no potential ongoing risk

The anticipated environmental improvements, predicted by pilot testing, mirrored the actual improvements, observed in the field, provided certainty in the outcome at all stages of the remediation.

This confidence ensured that the Client could commence development of the site with certainty that environmental risks were resolved.